OUR TECHNOLOGY

SEE IT IN ACTION

Experience the Difference

BUTTON EFFICIENCY IN COBOT PROGRAMMING

Streamlined Operations

• 80% of programming functions at your fingertips

• No more cycling through modes–access key operations instantly

Time-Saving Design

• Eliminate mode-switching delays common in single-button

• Perform frequent operations without interruption

Enhanced Productivity

• Reduce programming time significantly

• Ideal for use of operators

HARDWARE

RB-RING

SOFTWARE

WHY RB-X

Wireless Control with Android & WINDOWS

Seamless Access, Anytime, Anywhere

The RBW software runs on both Android and Windows operating systems. Users are free to choose any device with Android or Windows OS they like, from tablets to mobile phones.

Multi-use functionality

One License, Unlimited Possibilities

A single RB-X license covers MIG/TIG welding, laser welding, grinding, and plasma cutting—bringing all key processes together in one unified system with no extra add-ons needed.

WELDING MACHINE AGNOSTIC

Unlimited Compatibility, Maximum Flexibility

RB-X offers broad compatibility, integrating smoothly with most major welding machines. Its brand-agnostic design keeps your setup flexible, scalable, and ready for future growth.

ADVANCED WEAVING

Master Heat Control with Precision

Tailored Weaving for Every Weld. RBW’s weaving feature allows for highly controlled welding with adjustable patterns (circle, trapezoidal, sine wave, triangle, c-wave) and parameters.

TOUCH SENSING

Consistent Precision, Even When Parts Aren't

The touch sensing feature utilizes the torch nozzle to detect small discrepancies in part geometry, and is a default feature on the RB-MIG, regardless of the welding machine used.

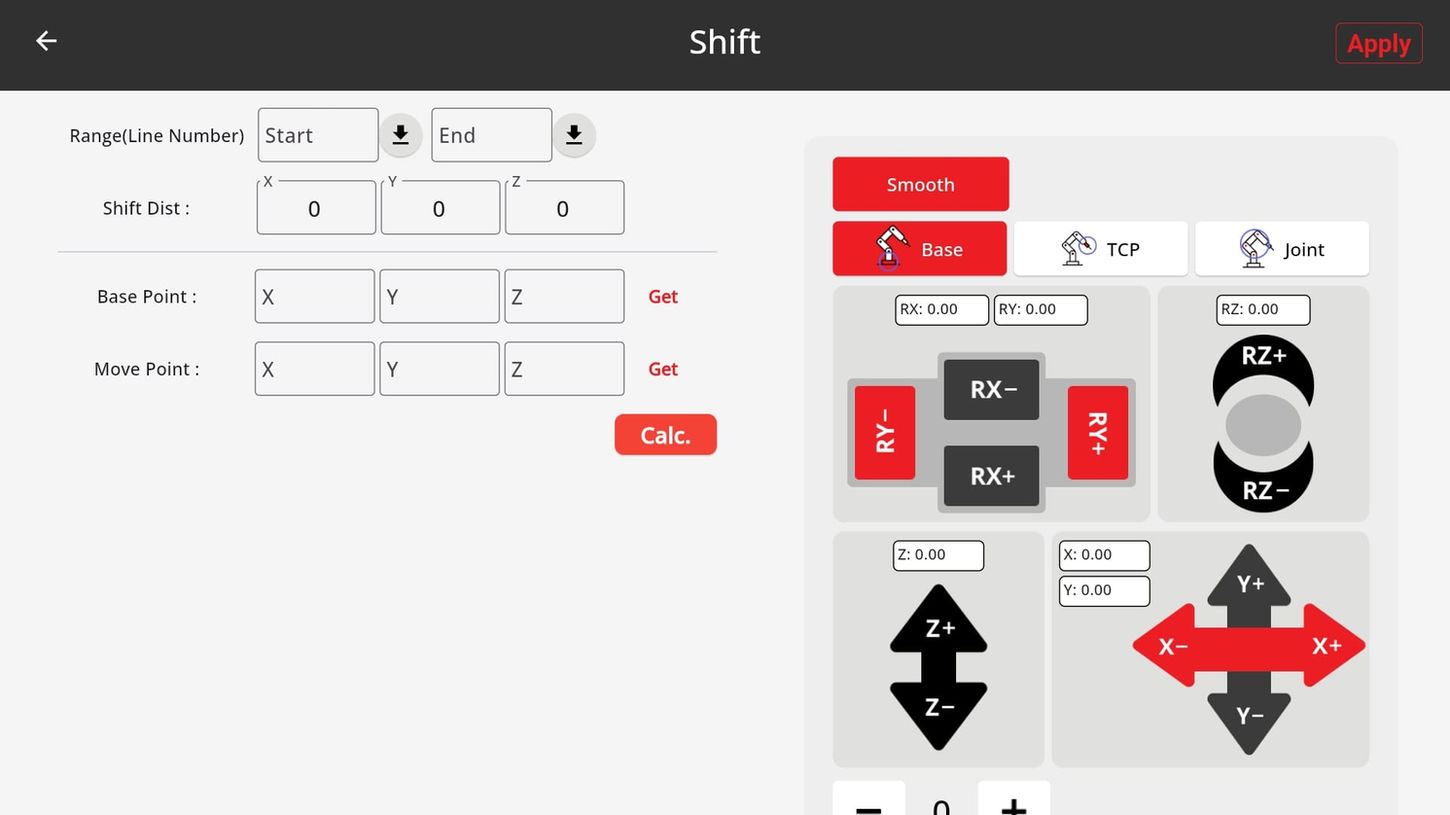

OFFSET (COPY & PASTE)

Cut Programming Time, Boost Productivity

The RBW Offset / Copy & Paste feature significantly reduces programming time for groups of identical workpieces with the shift, copy, cut and paste functions, available with all RBW systems.

PROGRAM SCHEDULER

Cut Idle Time, Boost ROI: Up to 4x Productivity

The RBW Program Scheduler is designed for users to schedule up to four program sequences and execute them in any order, enabling customized cells and low-downtime workflows.

Multi-Pass

Consistent Quality, Automated Layering

RB-X streamlines multi-pass welding by repeating paths with accurate offsets, ensuring consistent layer buildup and improved weld quality, ideal for thicker materials and demanding joints.